The Machine Shop is dedicated to taking the theoretical knowledge learned in a classroom environment and applying it to real world tactile solutions.

The shop contain a spectrum of equipment and technology ranging from simple hand tools and measuring equipment to fully CNC controlled multi-axis mills and lathes. It has become an unmatched resource, accessible to students and staff across multiple disciplines and departments.

Shop access

Once I create a CORAL account, what else do I need to do before using the shops?

- Register for shop access

- Attend an in-person training session for EACH shop (machine shop, composite shop,

mechanical test lab) you plan to use. Contact Machine Shop manager for machine shop

training availability. - Complete the Machine Shop Quiz and EH&S fire extinguisher training after attending the

in-person training.

○ Machine shop quiz

○ EH&S online fire extinguisher training

Hours (subject to change):

Shop availability varies depending on scheduled lab classes and safety classes.

Equipment

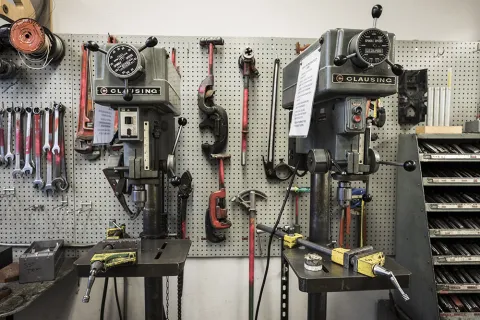

The tool room contains the most commonly needed powered and non-powered hand tools, cutting bits, and drill presses.

Vertical bandsaws

- JourneyMan (19.5’’ throat) for metals and plastic

- DOALL 30M (31’’ throat) for sheet metal and composites

Horizontal bandsaws

- Wellsaw 58B (3.5” X 9” max capacity)

- HYD MECH S-20 (12” x 14” max capacity)

Wet cut tile saw

- RIGID 8 in. 12 Amp Wet Cut Tile Saw

For student use, the abrasives area contains a pedestal grinder, a belt grinder, and two pedestal mount deburr wheels.

The welding/fabrication area is home to a Miller Syncrowave 350 Tig/Stick Welder, a Miller 250 Mig Welder set up for mild steel.

Manual/2-axis CNC Mills

All mill users are required to begin their training on TRAK manual/2-axis CNC knee mills outfitted with Southwestern Industries SMX controllers.

TRAK 3 axis CNC mills

TRAK DPM SX3P Manual/2/3 axis bed mills are the gateway machines into 3-axis programming, and 40 taper tool holders.

HAAS TM-1 P

The HAAS TM-1P is for metals cutting. It features a 10 tool changer, full enclosure, flood coolant, and 3+1 capability. Training is available to students only after they have mastered the TRAK DPM machines.

HAAS VF-3

The HAAS VF-3 is a dedicated fully enclosed 3 axis machine. Training is available to students only after they have mastered the TRAK 3 axis CNC mills programming and operation.

Manual lathes

All lathe users begin their training on one of our 14x40 engine lathes.

HAAS TL-2

Two HAAS TL-2lathes are available for training after the student has mastered the Manual lathes, and has a project requiring CNC functionality.

HAAS TL-3

The HAAS TL-3 is available to those students who have mastered the TL-3 Lathes.

We have three sizes of arbor presses as well as a Dake 75H hydraulic press.

Available only to advanced users machining foam and wood is a MultiCam 7000 series 3 axis CNC router.

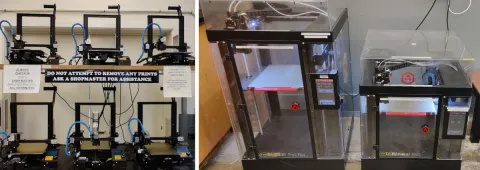

- Creality Ender 3 Pro printers are available to users with minimal training. For consistency and reliability we print exclusively with 1.75mm PLA. No alternative materials are allowed.

- Raise3D Pro 2 & Pro 2 Plus has a larger print platform and larger 0.6mm and 0.8mm nozzle. This machine also prints with 1.75mm filament. This machine can print PLA, ABS and PETG.

- Einscan Pro HD Scan parts on the automated turntable, or go hands-free with highly detailed scans for parts up to the size of a basketball, and high-resolution rapid-scanning of large objects.

A downdraft table with compressed air drops is available for hand trimming and sanding of composites, foam, and wood.

The Torchmate 4505 is a powerful plasma cutter with a 5x5 cutting table.

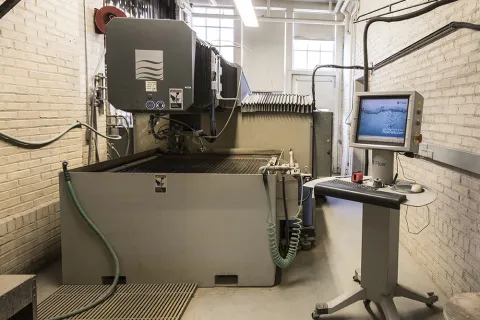

A FLOW Industries 4’x4’ waterjet cutter service is available for certain projects. Accessibility varies depending on the part geometry as well as the number of parts that need to be cut. A budget number will need to be supplied for operator/programmer time.

A Kern LC50 Laser cell is available to certified shop users after proper training.

Location

The Machine Shop is located in the Engineering Annex (EGA 116) behind the Mechanical Engineering Building. The C15 parking lot resides between the two buildings.

Safety classes

You will need to sign up for shop safety classes before you can access the shop. The shop is for working on official UW sponsored projects including student technical clubs and official research. All shop users must be a active students, staff, or faculty members of the University of Washington.

The sign up sheets for the shop safety classes are posted in the Machine Shop (EGA 116) the first day of each quarter at 9:00 AM. Attendees must sign up in person, and we recommend getting in early, because the classes fill up very quickly, within a half-hour of being posted. If you aren't here early, it's unlikely you will get in.

The safety classes are free and not for credit. They are held on three separate days, each a week apart, and each class is approximately 2 hours long. We do not schedule special class times for individual schedule conflicts, because everyone's schedule is different. If you cannot attend the safety classes held during a particular quarter, the soonest you will be able to complete them is at the beginning of the next quarter.

Similar facilities

Other shops that allow student access besides ours here on campus:

- Co-Motion MakerSpace in Fluke Hall

- Area 01 multi-use space in Maple Hall

- Physics Student Machine Shop

- The Mill in McCarty Hall

- The Chemistry Machine Shop

- The 8

We don't do much work for hire anymore, due to the huge load of students we have to monitor, as well as other maintenance and shop improvement. If you need work done soon, we recommend talking to any of these excellent resources: