A wave-energy converter device, composite materials for aircraft, an improved handcycle, tougher compostable plastics and an overhead mobility system were among the prototypes showcased at the 2024 Mechanical Engineering Capstone Expo.

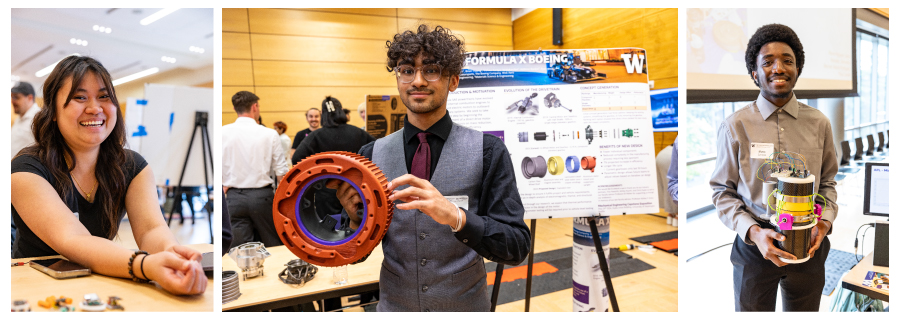

From left to right: Student showcase a microbattery, custom electric motor design and a buoyancy-controlled underwater oceanographic sensing device. Photo by Matt Hagen.

At the spring event, undergraduate students presented their capstone senior design projects to the ME community and industry members through posters, prototypes, exhibits and demos. Students have worked on their projects, many of which are interdisciplinary, for the past two quarters.

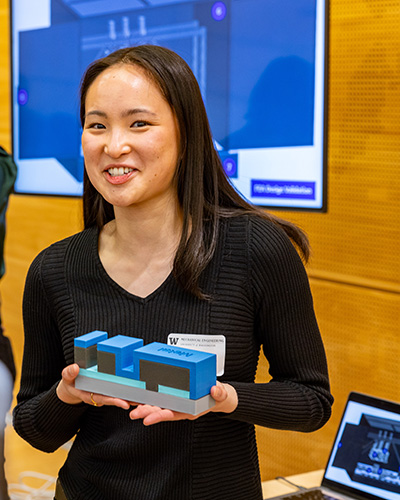

One project involved developing a laser system tool (prototype shown here) for scribing solar cells made from perovskite materials. Photo by Matt Hagen.

Many projects were sponsored by industry leaders. A project sponsored by PACCAR focused on creating an autonomous driver vehicle interface for a test truck to replicate the driving experience of a mechanically linked control system. A capstone sponsored by The Boeing Company worked to characterize and improve the flow of inert gas in a metal additive manufacturing machine for more consistent material properties.

Other capstones were hosted by faculty and proposed by students. The event also included the results of a photo contest and exhibit awards judged by a panel of experienced engineers. The Adaptable Housing Project Anti-Sway Control project team was recognized for best design (mechatronics) and the Composite Door Stop Beam Design team, sponsored by The Boeing Company, received an award for best design (general).

One project involved developing a laser system tool for scribing solar cells made from perovskite materials. Laser scribing “scrubs” solar cells to straighten edges and reduce defects, which optimizes the cells’ manufacturing and performance. The students created a laser system that could pattern a larger area than the current system at the Washington Clean Energy Testbeds, the UW’s open-access lab for climate tech innovation. The students were mentored by Devin MacKenzie, associate professor in ME and materials science & engineering and Testbeds technical director.

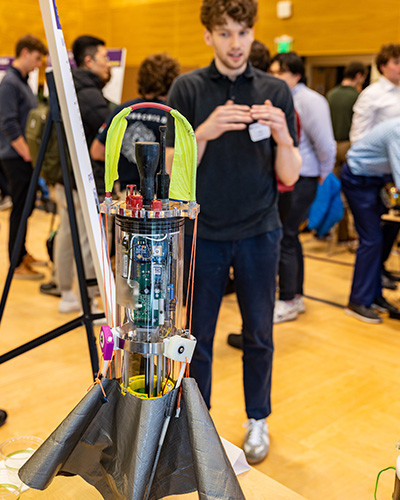

One team of students created a drag screen for the MicroFloat, a buoyancy-controlled underwater oceanographic sensing device. Photo by Matt Hagen.

“I was interested in this topic because it involved three lasers with different effects, a motion system and 3D printing,” says team member Sky Song (BSME ’24). “I learned the importance of communicating with industrial vendors who provided our materials, and taking shipping into account.”

A project focused on improving the MicroFloat received the communication award for most effective exhibit. The MicroFloat is a buoyancy-controlled underwater oceanographic sensing device that helps scientists gather data about salinity, temperature and more. The project was sponsored by the UW Applied Physics Laboratory and mentored by MicroFloat inventor Trevor Harrison (ME Ph.D. ’20).

The float’s internal motor actuation can lead to high power consumption and data collection noise. The students created a removable drag screen for the float to reduce the motor actuation while increasing hydrodynamic drag and data accuracy. They found a slight improvement after testing it in a controlled tank and in Lake Washington on a boat.

“I chose this project because of the hands-on mentorship,” says Carrie Lin (BSME ’24). “It was my first time working with fluidics, which was a learning curve. It was exciting to learn new things.”

Originally published July 8, 2024