By Andy Freeberg

Photos by Dennis Wise / University of Washington

June 8, 2020

UW fabrication engineers help meet the rising need for supplies to protect medical staff and treat patients with COVID-19.

Soon after the potential impacts of the novel coronavirus became apparent in the Seattle region, UW Medicine knew a major concern would be having sufficient personal protective equipment (PPE) to keep healthcare workers safe. Responding to their call, specialists in digital fabrication and manufacturing from across campus quickly mobilized, lending their expertise and facilities.

Through the Center for Digital Fabrication and the Solheim Manufacturing Science and Technology Laboratory, ME researchers have been collaborating with UW Medicine, the Paul G. Allen School of Computer Science & Engineering and other colleagues from academia and industry to meet with front-line providers and innovate PPE — including face shields, masks and medical gowns — so that hospitals can remain well-supplied. These photos highlight some of their ongoing efforts, all of which are in various stages of validation, approval and dissemination for use around the world.

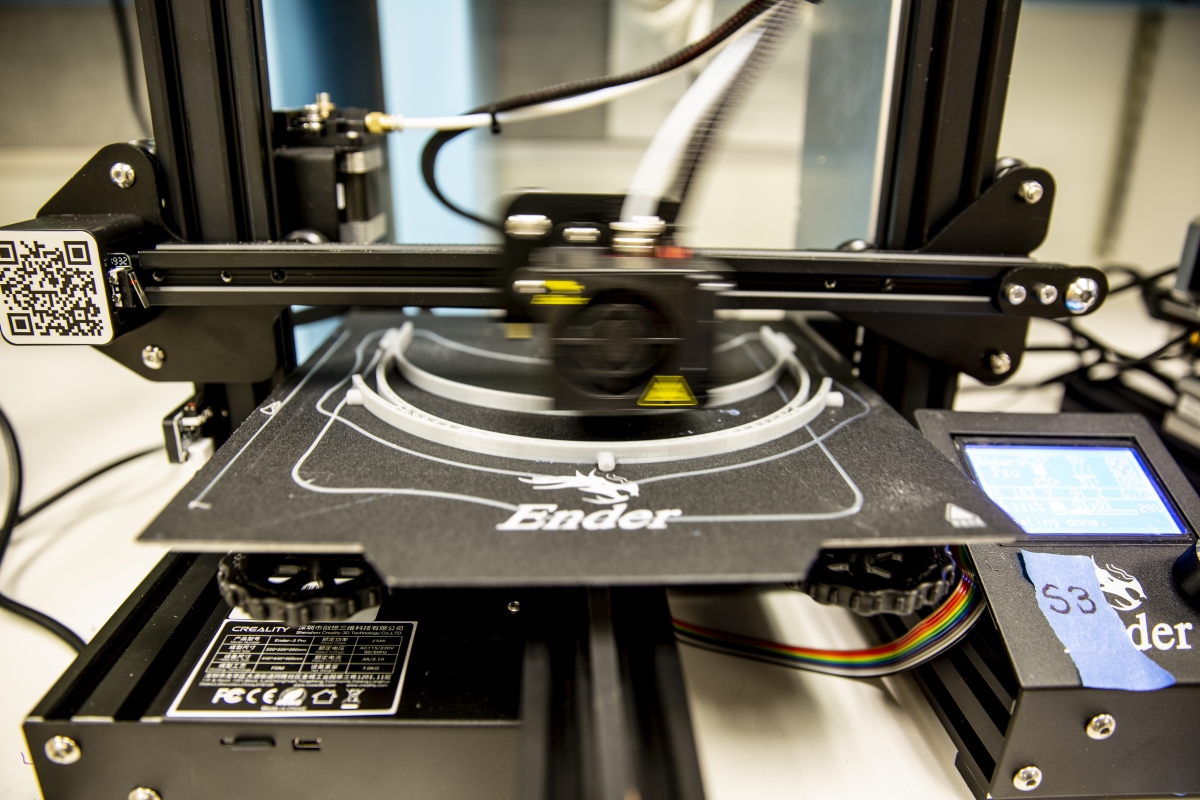

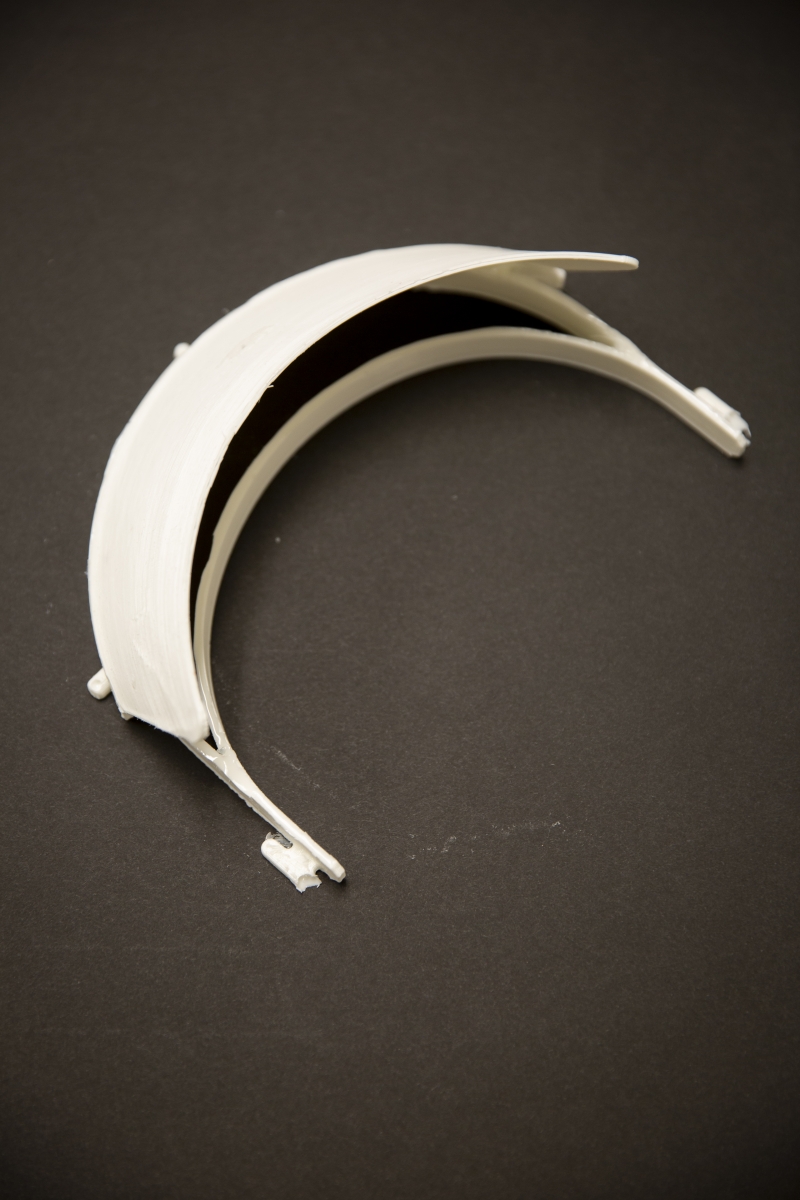

In conjunction with an effort driven by UW Medicine, 3D printers across campus busily worked to manufacture cradles to hold face shields. More than 1,000 were delivered with a substantial number contributed by ME. (Read More)

Graduate Students Daniel Revier and Kelly Mack from the Make4All lab cut UW-designed medical gowns on ME’s digital fabric cutter. The gowns are the first disposable isolation gown designs being vetted by the FDA and shared through the NIH print exchange with simple instructions for how to make them in other communities in need of protective gowns.

3D printing isn’t the only way to quickly go from design to product. Here ME professor Mark Ganter uses casting to make a face shield cradle. Innovating with other manufacturing techniques like injection molding and vacuum forming will be critical for industry to ramp up PPE production.

Masks may be the most well-publicized of COVID-19-related medical PPE. The UW Center for Digital Fabrication (DFab) has been working on a number of projects to validate, design and prototype them. These include filtered surgical masks (shown here), respirator masks and non-rebreather masks.

ME assistant professor Jeffrey Lipton (left) works with graduate student Soumya Jindal of the Makeability lab to prepare a study of medical mask design. As a co-director of DFab and member of the UW COVID-19 Task Force, Lipton has been a leader in UW’s effort to confront medical PPE supply challenges.

Graduate student Soumya Jindal of the Makeability lab works on an iteration of a 3D printed medical mask prototype. While masks are used for a variety of reasons in the healthcare environment, many share a common design need to fit snugly and comfortably on a range of faces so that breathing can be controlled through tubes and filters.

To learn more about UW’s COVID-19 fabrication projects, visit the DFab website.